TIG welding, or Tungsten Inert Gas welding, is a highly versatile and precise welding technique that is ideal for applications requiring strong, clean welds. This process uses a non-consumable tungsten electrode to create high-quality welds with minimal spatter, making it one of the most reliable methods in the welding industry. At Micro Weld, we specialize in providing TIG welding services that meet the demanding needs of industries such as aerospace, automotive, and medical device manufacturing.

Why You Should Choose Micro Weld’s TIG Welding Services for Your Projects

TIG welding is well-known for producing clean, precise, and high-strength welds, making it the preferred method for projects where the quality of the weld is crucial. One of the main advantages of TIG welding is that it allows for complete control over the weld pool, ensuring that the finished product is free from contaminants such as porosity or oxidation. This makes TIG welding especially important in industries that require flawless welds with both structural integrity and aesthetic appeal.

At Micro Weld, our TIG welding services are designed to cater to a wide variety of materials, including stainless steel, aluminum, titanium, and exotic alloys. This versatility allows us to serve a broad range of industries, from aerospace and automotive to medical device manufacturing, where precision and durability are critical.

How Microscopic Laser Welding and TIG Welding Work Together at Micro Weld

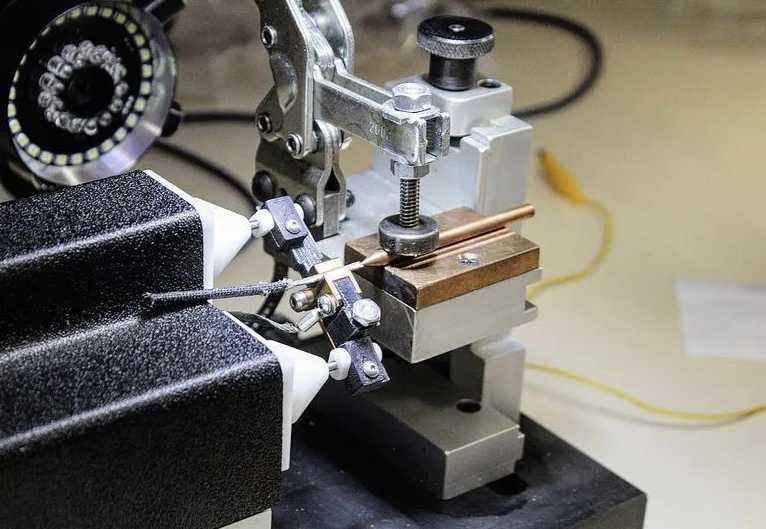

While TIG welding excels in creating strong, clean welds for large-scale and structural components, microscopic laser welding serves specialized needs that require extremely precise, small-scale welds. These two techniques often complement each other, especially in industries like aerospace and medical device manufacturing, where both strength and precision are required in the same project.

For example, TIG welding is used to join larger components, ensuring structural integrity, while microscopic laser welding is employed to handle intricate and delicate details that require high levels of accuracy. At Micro Weld, we are equipped to provide both TIG welding and microscopic laser welding services, offering complete solutions for all your welding needs.

Why Micro Weld is Your Trusted Partner for TIG Welding Services

With years of experience and a team of highly skilled technicians, Micro Weld offers top-tier TIG welding services that guarantee exceptional results. Whether you need high-precision welds for medical devices, aerospace components, or automotive parts, Micro Weld has the expertise and equipment to meet your welding requirements.