While some welding systems are designed as one unit, a stud welding machine, either a capacitor discharge (CD) or a drawn arc system, is made up of three parts. This offers several advantages to customize or change different components, making the system more versatile and flexible in handling all type of stud weld jobs.

It is important to keep in mind that CD and drawn arc systems use different technologies and parts and components cannot be mixed and matched between the system. Most CD stud weld equipment can operate either for contact or gap welding, but it is important to check this with the manufacturer before making an incorrect assumption.

The Power Source

The power source is more than just power for the handheld tool. It is the control system to allow the operator to configure specs for the specific job at hand. New technology in many of these stud welding machine models provides a greater number of features and functions to make on-the-job adjustments quick and easy.

Look for systems with built-in maintenance trackers, prompting the operator to complete required maintenance after a specific number of welds has been completed. Other features on drawn arc system such as hammer mode to clear the surface of rust and paint is a great feature to consider.

Cables

Both ground and extension cables are also important for optimal and safe operation of equipment. This becomes even more important on outdoor jobs or when the system is portable and not permanently mounted with cables run to workstations.

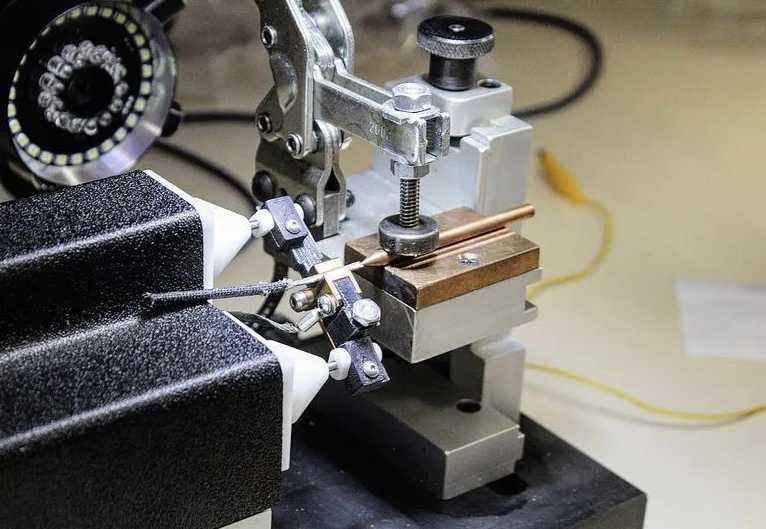

Handheld Tools

Handheld tools for a stud welding machine of any type should be ergonomic and comfortable for the operator. They should be designed with a gentle trigger pull and to be lightweight and compact, allowing them to be used in any position with ease.

Before choosing any stud welding system, take the time to compare it to others on the market. This is helpful in considering the options and seeing what is available between different brands.