There are a lot of different uses for aluminum bar, although it is typically considered the most appropriate aluminum alloy for aerospace designs. To get a better understanding of the versatility of this type of aluminum bar learning more about the properties which make it such as a good option is important.

Aluminum bar is what is known as a precipitation hardening aluminum alloy. This means it is heat treated and age hardened through a special process to increase the yield strength without adding any weight to the metal. Since the aerospace, automotive and even manufacturing industry needs lightweight yet durable metals, this makes a perfect combination.

Production Methods

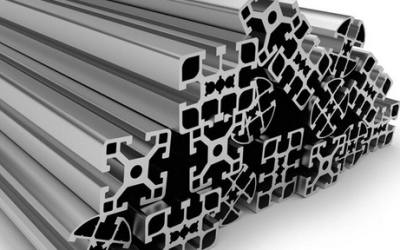

Top producers of aluminum bar may use several different options when creating the bra. Rolling and extrusion are the most common processes which allow for quality control and consistency throughout the final product. With this process long, uniform continuously formed bars are created which are then cut into workable lengths.

These lengths have to be precision cut to exacting specifications either at a metal service center or through the manufacturer. Typically a specialized aluminum metal service company is the best option as most end-users won’t order the quantity needed to have the cutting done through an international aluminum manufacturing company.

It is also possible to produce aluminum bar through coiling and drawing. This creates a long coiled final product which can be shaped into any option required. This may include square, rectangular or round bars in a variety of different sizes for any type of application.

Uses of Aluminum Bar

In the aerospace and aircraft industries aluminum bar is used for structural design, particularly for wings and larger structures such as fuselages. It is highly resistant to corrosion, and it is strong yet lightweight, making it a go-to option for many different applications.

For the same reasons aluminum bar can also be used in creating automotive parts such as wheel spacers. With a good level of resistance to corrosion by salt water, it is also found in marine applications such as structural components for yachts and small boats.

The durability and weldability of aluminum bar also makes it an excellent choice for many manufacturing processes. This includes the construction of ultra-high vacuum chambers and for manufacturing lines and processes.

Today, products such as Acc-u-rod® and Acc-u-bar® provide significant and definite advantages over standard aluminum bar. It is straighter, has improved diameter tolerances and higher strength for even the most demanding jobs and requirements. With these options and highly controlled precision cutting, it is possible to get just the aluminum bar required for machining for any job.

At Howard Precision Metals, Inc. we have an excellent selection of aluminum bar on hand. To see more or to place an order go to Howardprecision.com.