In today’s fast-paced manufacturing environment, accuracy is critical for ensuring the quality and uniformity of complex components. CNC machining is a technology known for its extraordinary precision. This automated approach has transformed sectors that rely on the production of delicate components, providing exceptional consistency, speed, and reliability. Machinists may attain the highest level of detail with computer numerical control (CNC), guaranteeing that all products meet rigorous criteria.

The Advantages of Precision CNC Turning

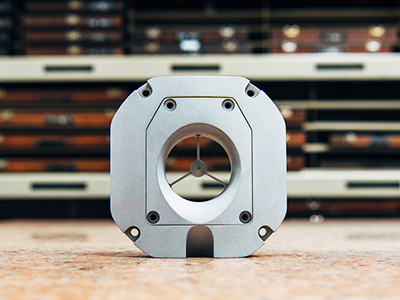

CNC turning is a highly efficient machining process that involves rotating a workpiece on a lathe while using a cutting tool to achieve the required form. Computer-controlled turning operations differ from traditional methods by using advanced control systems, which improve precision and reduce human error. This method allows for highly exact component replication, maintaining constant quality throughout the manufacturing process. One of the primary advantages of CNC turning is its ability to handle complex geometries with ease. This capacity to accomplish precise tolerances and sophisticated designs is extremely essential in industries like aerospace, automotive, and medical device manufacture. CNC machines run continuously, allowing for large production while adhering to strict standards. This leads to a reduction in production costs without compromising the quality of the final product. The CNC turning process is flexible, allowing producers to create a wide range of components, from simple circular pieces to more complex designs.

Applications Across Diverse Industries

Precision CNC turning offers numerous advantages across a wide range of sectors. The aerospace sector uses CNC turning to produce parts with pinpoint accuracy, such as turbine blades and engine components, which must meet high safety and performance standards. Similarly, the car industry uses CNC turning to produce a variety of engine parts, including crankshafts and gearboxes. Precision is essential in the medical industry, particularly when manufacturing prosthetic devices, surgical equipment, and implants. CNC turning enables producers to meet the stringent specifications required for these high-risk applications. The ability to mill materials like titanium and stainless steel with high precision means that each part works flawlessly within the human body. Beyond aerospace, automotive, and healthcare, CNC turning has made its way into electronics, where it is utilized to build complicated connectors and housings.

Ensuring Quality Through Advanced Technology

With the advancement of CNC technology, businesses are better equipped to satisfy the ever-changing needs of the worldwide market. Developments in software and technology boost the accuracy of CNC turning by enabling real-time monitoring and corrections. As a result, producers can spot possible difficulties before they occur, resulting in less waste and greater efficiency. Quality control is an essential aspect of the CNC turning process, with many machines outfitted with automated inspection equipment that compares each part to predetermined tolerances. It ensures that each product that leaves the production line is of attractive quality. As industries expand and the demand for higher accuracy grows, CNC turning will remain an important technology, fostering innovation and guaranteeing that manufacturers can fulfil the most stringent specifications. Precision CNC turning is an appropriate tool for modern industry.