Working with a variety of materials, many of them metal, can present certain challenges during the production process. That is where welding can wind up being a valuable process to trust.

Welding production offers many advantages when working with this wide array of materials. A skilled production welder can provide the following advantages for your production needs.

Design

From a design aspect, welding production can really provide substantial benefits from an aesthetic standpoint. Welding offers far less bulky seams that are lightweight while offering a higher strength.

There is also greater flexibility when it comes to designing parts or components. Best of all? The low processing costs will ensure that you stay within your budget no matter what you have in mind, all of which is possible with the help of welding.

Efficiency

Another huge benefit of welding production is the improved efficiency that it offers. Having welded seams is much more reliable than any other type of adhesive or joint product. Using glues can offer certain benefits, but there is the matter of strength and reliability to consider, especially where higher temperatures are involved.

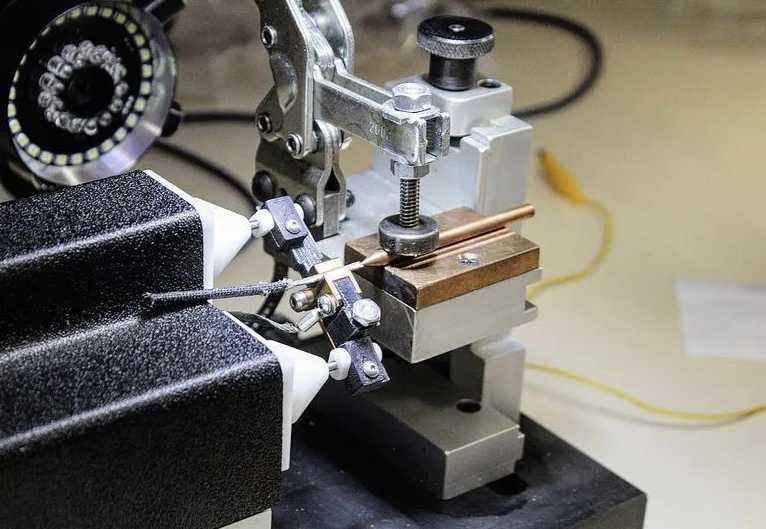

By going with welding, you can ensure greater reliability and efficiency. There is less room for human error, especially with machinery that controls speed, angle, and heat. It is a great way to improve production, reduce labor costs, and ensure greater accuracy, stability, and reliability in those essential pieces and components.